Saito's New Engine: FG-90R3

The following users liked this post:

Didier (08-18-2020)

The following users liked this post:

Didier (08-18-2020)

#403

Senior Member

Thank you very much. This was the 15th flight I guess. The first 4 flights I used a Biela 22x12x3 WW2 prop. But I did not like it all. To much revs and no speed. Now I use A Ramoser varioprop 25F with 22.7” 3 blades. Pitch adjusted around 14,5”. Engines revs around 5300 on ground and 6900 in air. This prop is so efficient. It pulls the Zero like a freight train. I hardly use full power. Only during vertical and loops. Needle settings: Around 5 turns on low and 4 on high.

#404

It sounded perfect in the air . I'm not thrilled with the static rpms on the ground with the Biela 22x12x3 ww2 either. Too many revs on the ground will be me way too many unloaded in the air. I'll look into the Ramoser Vario prop system . I'm not sure if they have a US distributor .

#405

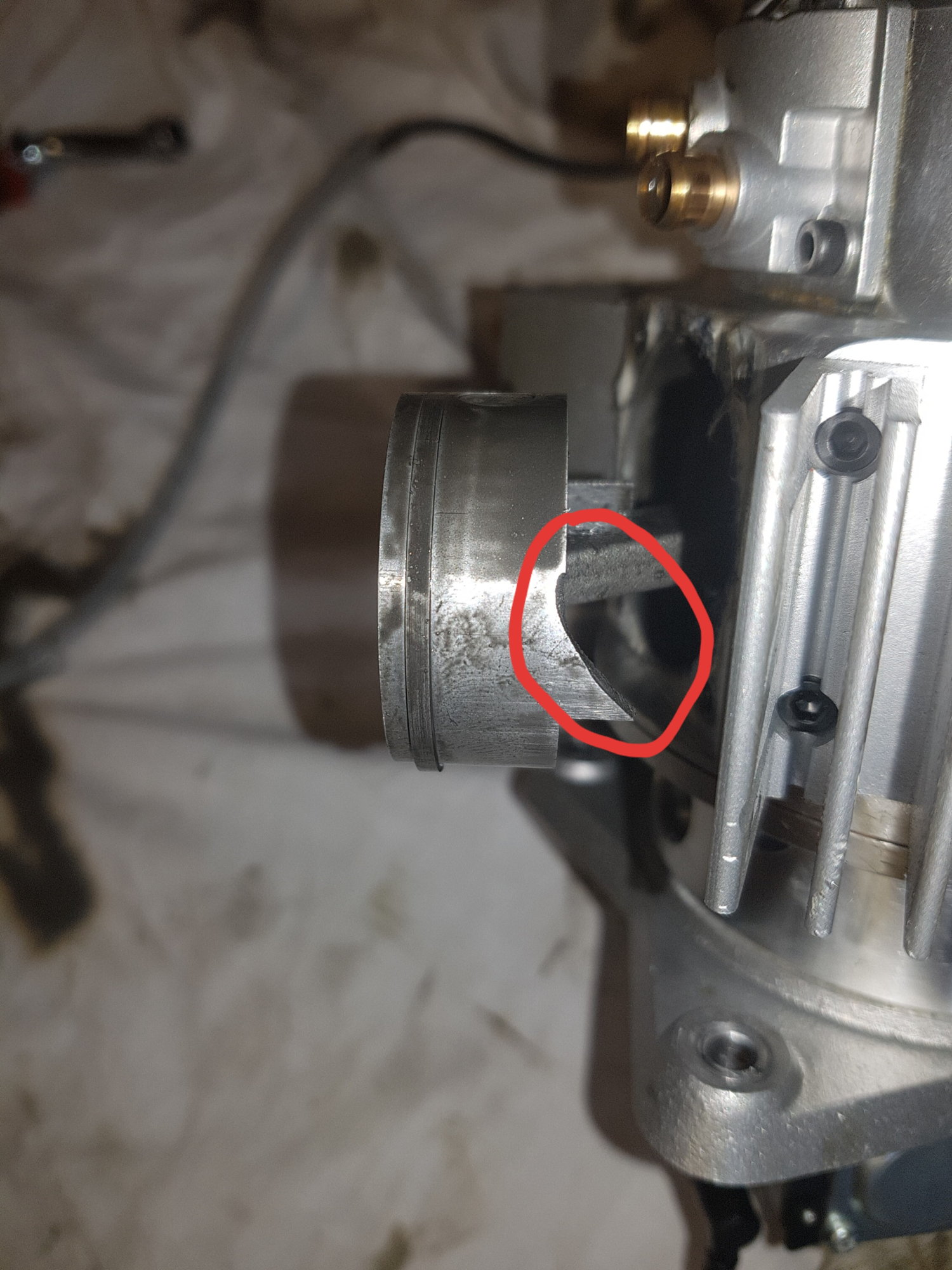

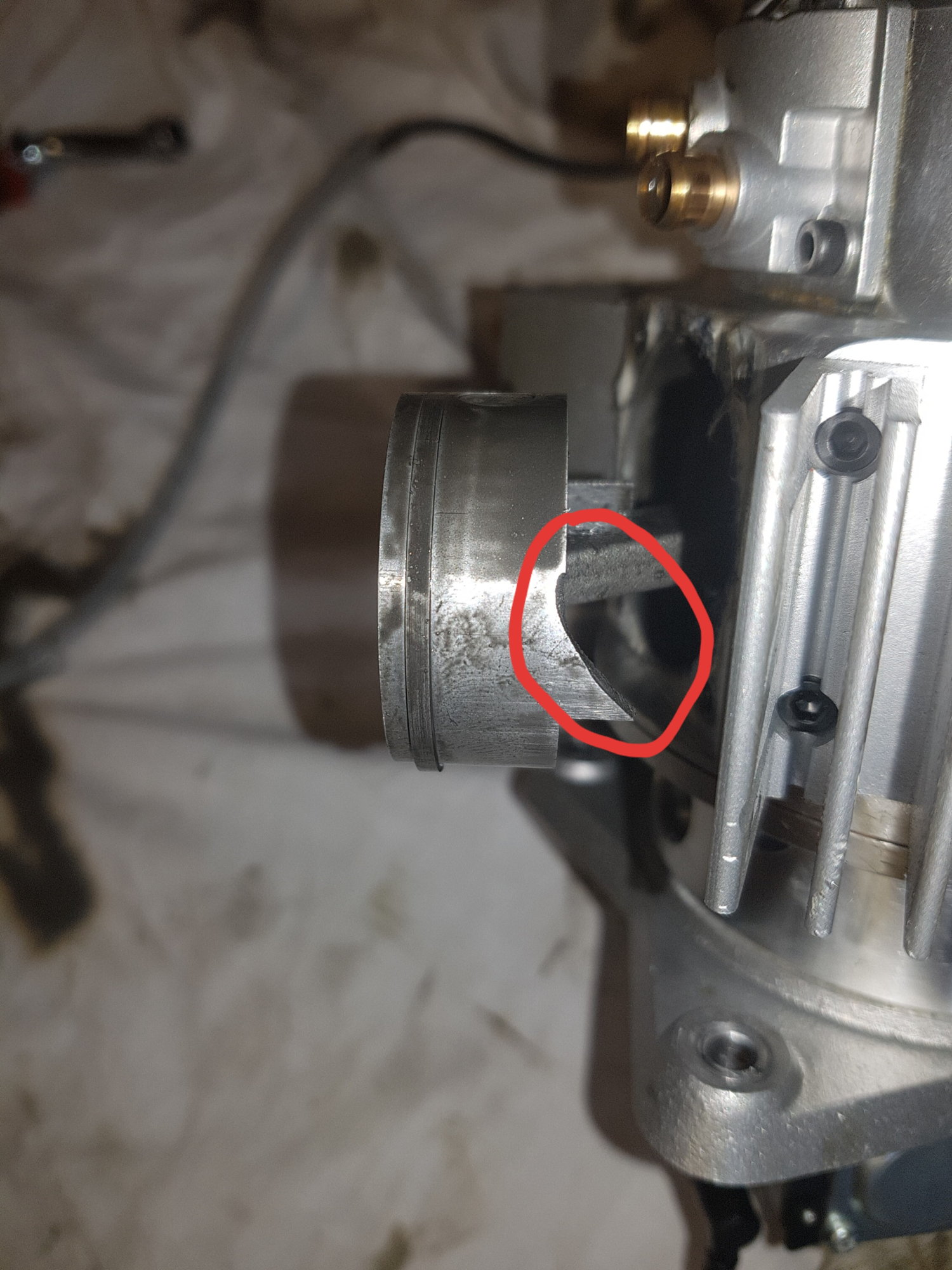

Said news, my engine failed....

My last flight was week ago and there was no issue at all, I didn't hear any strange noise whatsoever. After flight I took my plane home and it was staying there untill yesterday when I went to the airfield again. After refuelling I wanted to prime engine but prop stucked after turning 180deg. Then I tried to turn clockwise but again it stucked after half turn. I removed spark plugs and looked at piston heads for any signs of loose metal particles but it looked ok. So I went home, put plane up side down but still something was blocking engine. When I put my plane vertically on to the nose and to the tail I tried again to turn propeller and....it turned freely all way around. I decided to open top cylinder to look at the crankcase and bingo: bottom part of piston head found broken with remainings in the crankcase.

This is so disappointing. Such a failure after just few flights.

Any ideas what might cause such a failure?

My last flight was week ago and there was no issue at all, I didn't hear any strange noise whatsoever. After flight I took my plane home and it was staying there untill yesterday when I went to the airfield again. After refuelling I wanted to prime engine but prop stucked after turning 180deg. Then I tried to turn clockwise but again it stucked after half turn. I removed spark plugs and looked at piston heads for any signs of loose metal particles but it looked ok. So I went home, put plane up side down but still something was blocking engine. When I put my plane vertically on to the nose and to the tail I tried again to turn propeller and....it turned freely all way around. I decided to open top cylinder to look at the crankcase and bingo: bottom part of piston head found broken with remainings in the crankcase.

This is so disappointing. Such a failure after just few flights.

Any ideas what might cause such a failure?

#407

It's difficult to determine a cause by only 2 photos but a guess would be that if the only detached part is the piston skirt that the skirt was either fatigued or was struck by something in the crankcase. I would venture a guess based on the aluminum content in the oil that there was some high speed piston chatter that fatigued the skirt and it failed .

#410

Hi Didier,

Great setup you have with your Zero

I also bought a Ramoser varioprop 25F with 21.8" 3 blades for a FW 190

Since this is my first varioprop, can you give me some advice how to setup the prop?

Thanks!

Great setup you have with your Zero

I also bought a Ramoser varioprop 25F with 21.8" 3 blades for a FW 190

Since this is my first varioprop, can you give me some advice how to setup the prop?

Thanks!

#411

Darod,

That sucks. Engine should not break like that.

I assume you had it properly baffled.

Any idea what your RPMs in the sky were after prop unloading? Temps while flying?

jim

That sucks. Engine should not break like that.

I assume you had it properly baffled.

Any idea what your RPMs in the sky were after prop unloading? Temps while flying?

jim

#412

That day I made 2 flights only. Below are graphs from onboard telemetry. As you can see, it's obvious that failure happened during 2nd flight. I have also video from 2nd flight but I didn't notice anything suspicious.

1st flight

2nf flight

2nd flight video:

https://www.youtube.com/watch?v=IlDW...ature=youtu.be

#413

Hi Darod,

The fact that you didn't notice anything during and after the flights means that the skirt was still on the piston during the last flight. However, I suppose that if you landed a few minutes later, you probably had a dead stick landing.

While cranking the engine before next flight, the skirt probably broke completely of the piston.

I guess you were lucky not to crash that plane...

Carlo

The fact that you didn't notice anything during and after the flights means that the skirt was still on the piston during the last flight. However, I suppose that if you landed a few minutes later, you probably had a dead stick landing.

While cranking the engine before next flight, the skirt probably broke completely of the piston.

I guess you were lucky not to crash that plane...

Carlo

#414

Hi Darod,

The fact that you didn't notice anything during and after the flights means that the skirt was still on the piston during the last flight. However, I suppose that if you landed a few minutes later, you probably had a dead stick landing.

While cranking the engine before next flight, the skirt probably broke completely of the piston.

I guess you were lucky not to crash that plane...

Carlo

The fact that you didn't notice anything during and after the flights means that the skirt was still on the piston during the last flight. However, I suppose that if you landed a few minutes later, you probably had a dead stick landing.

While cranking the engine before next flight, the skirt probably broke completely of the piston.

I guess you were lucky not to crash that plane...

Carlo

#415

Senior Member

But lucky the plane is in one peace. If I look at your data the temp was rising to 160 degrees C. Is this the temp from the broken piston? Did you check the other cylinders as well?

I noticed in your data that the warm-up time of the engine is very short. I wait to go full power until the engine is at least 120 degree C. I don’t know of course if this was a contributing factor.

Last edited by Didier; 09-08-2020 at 12:02 PM.

#416

Senior Member

This is my first Ramoser as wel. Just follow the instructions. I use 22,7” HS blades though and adjusted it around 5400 RPM on ground (6900) in air with a pitch around 14,5”. This seems to be perfect for the Zero. Hopefully the 21.8” gives enough load for the Saito 90. Good luck!! 👍

#417

That is terrible the engine broke. 😏

But lucky the plane is in one peace. If I look at your data the temp was rising to 160 degrees C. Is this the temp from the broken piston? Did you check the other cylinders as well?

I noticed in your data that the warm-up time of the engine is very short. I wait to go full power until the engine is at least 120 degree C. I don’t know of course if this was a contributing factor.

But lucky the plane is in one peace. If I look at your data the temp was rising to 160 degrees C. Is this the temp from the broken piston? Did you check the other cylinders as well?

I noticed in your data that the warm-up time of the engine is very short. I wait to go full power until the engine is at least 120 degree C. I don’t know of course if this was a contributing factor.

#418

Hi Guys,

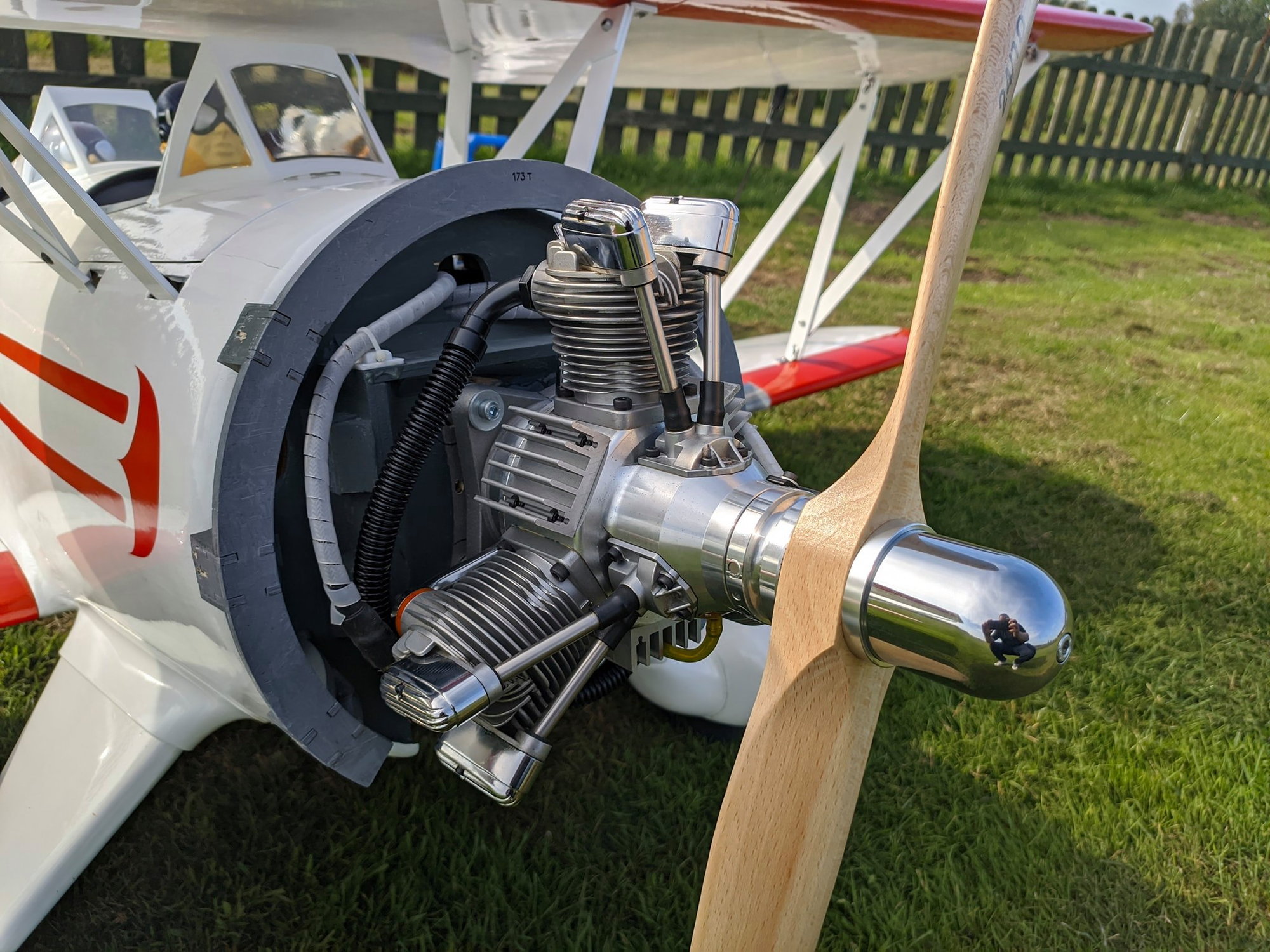

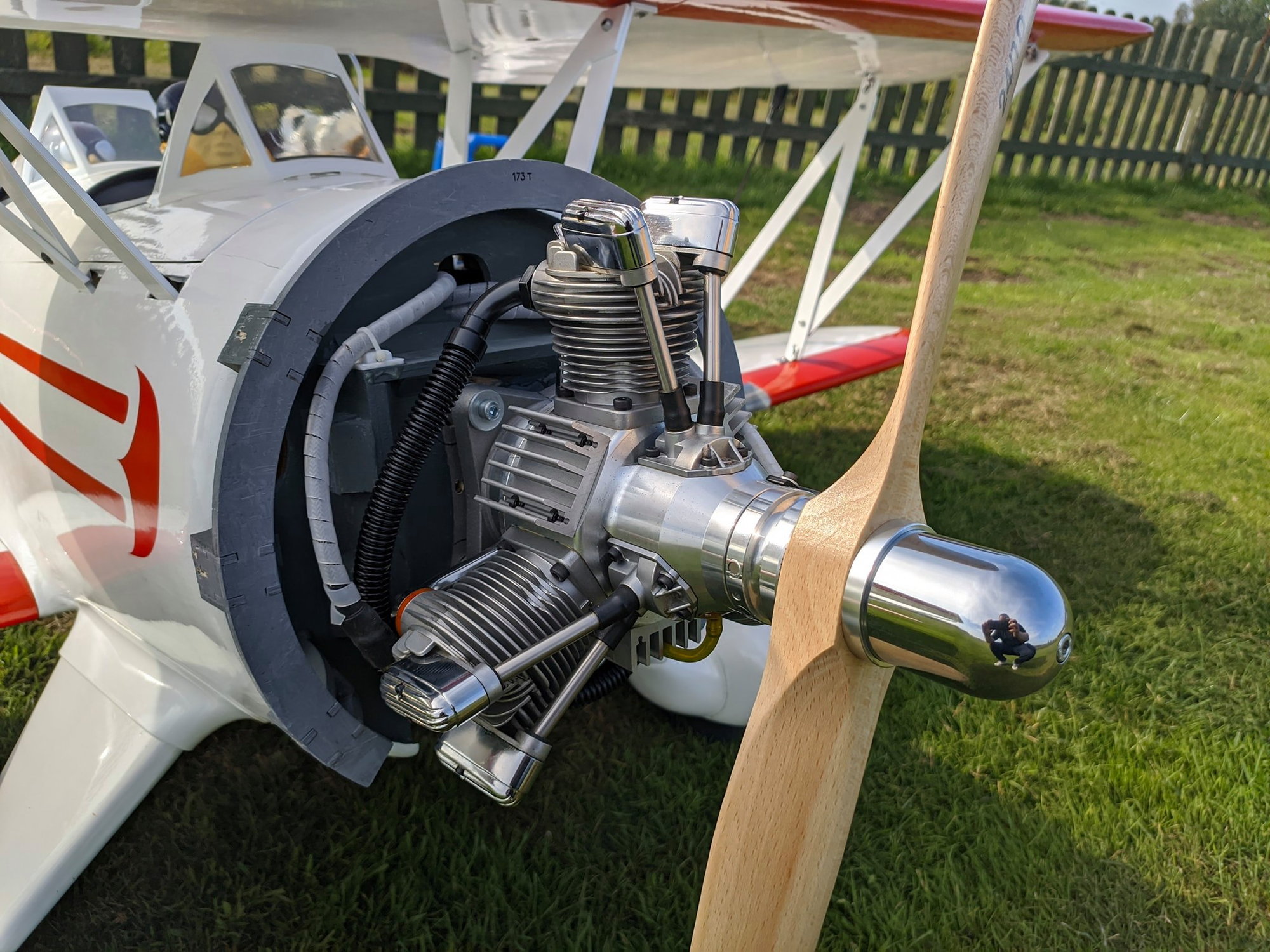

I have an fg-90 in a Phonex Waco and I find the top cylinder gets super hot compared to the bottom cylinders, its to the point where I have to just about idle around the sky as the temps on the top cyl jump to 150 – 160deg not long being in the air. the bottom temps are much lower.

Is this a baffling issue? or the high temp is normal for this motor, I think it would keep climbing if I didn’t back off?

I have an fg-90 in a Phonex Waco and I find the top cylinder gets super hot compared to the bottom cylinders, its to the point where I have to just about idle around the sky as the temps on the top cyl jump to 150 – 160deg not long being in the air. the bottom temps are much lower.

Is this a baffling issue? or the high temp is normal for this motor, I think it would keep climbing if I didn’t back off?

#419

Hi Guys,

I have an fg-90 in a Phonex Waco and I find the top cylinder gets super hot compared to the bottom cylinders, its to the point where I have to just about idle around the sky as the temps on the top cyl jump to 150 – 160deg not long being in the air. the bottom temps are much lower.

Is this a baffling issue? or the high temp is normal for this motor, I think it would keep climbing if I didn’t back off?

I have an fg-90 in a Phonex Waco and I find the top cylinder gets super hot compared to the bottom cylinders, its to the point where I have to just about idle around the sky as the temps on the top cyl jump to 150 – 160deg not long being in the air. the bottom temps are much lower.

Is this a baffling issue? or the high temp is normal for this motor, I think it would keep climbing if I didn’t back off?

What prop are you using? Baffles are a must for this engine. They should be about 25mm back from the front of the heat sink. This puts the baffles right around the engine center line. Make sure you have plenty of exit air out the back of cowl.

Dummy cowls are not the kind of baffles you need for the engine. I attached the baffles using some L brackets cut from aluminum.

Hope this helps,

jim

#420

Thanks for your reply Jim, i'm running a master aircrew 24x12. I dont have any baffling, so hopefully it sounds like that might be the issue.

Where do you find the best mixture setting?

Reading this thread some people appear to be running approx 6 turns high speed and 4.5 on the low? much different from the manual (the manual stated settings seem to be quite lean?)

Where do you find the best mixture setting?

Reading this thread some people appear to be running approx 6 turns high speed and 4.5 on the low? much different from the manual (the manual stated settings seem to be quite lean?)

#421

I also just installed my 84 in the Waco and test flew it with the cowl on no baffling....and it overheated. So I landed and removed the cowl and flew the rest of the day out.

This engine flew great in my baffled Yak 3U.

So it needs baffling in the waco.

This engine flew great in my baffled Yak 3U.

So it needs baffling in the waco.

#422

Thanks for your reply Jim, i'm running a master aircrew 24x12. I dont have any baffling, so hopefully it sounds like that might be the issue.

Where do you find the best mixture setting?

Reading this thread some people appear to be running approx 6 turns high speed and 4.5 on the low? much different from the manual (the manual stated settings seem to be quite lean?)

Where do you find the best mixture setting?

Reading this thread some people appear to be running approx 6 turns high speed and 4.5 on the low? much different from the manual (the manual stated settings seem to be quite lean?)

jim

#423

In terms of the Waco, baffles will help, but remember that air exiting the cowl is part of the equation. I'm still working through that challenge on my FW 190. Air exits are minimal.

jim

jim